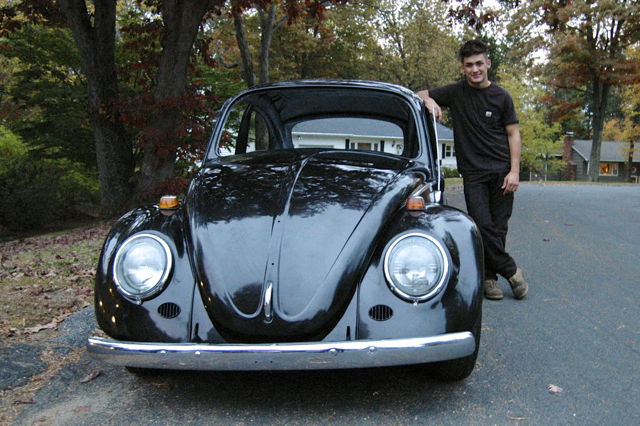

After 2 years Volky is now my daily driver, I can’t wait to slowly cruise to shows windows down and music blasting

Putting My 66 VW Back Together

A Fresh Lick Of Red

Ordered these dope steelies already primed off of eBay, I prepped them for paint and got spraying. My boss recently restored an old ford truck and had this paint left over. So why bother paying for paint when I can get it for free, one saturday when there wasn’t much business he let me paint them. While I was at it I also painted the fan shroud to the engine compartment which cools the engine down, aircooled. Vw beetle volkSWAGon

1966 VW Beetle Engine & Mechanics

This beetle was a mess when I got it. It had a mixture of 6 and 12 volt parts. I have no idea how it even ran. I’ve taken everything apart, painted the fan shroud and put new transmission mounts, axle boots and much more. I put in a new alternator and replace all the 6 volt parts with 12 volt. I’ll list all the details soon along with more photos.

1966 VW Beetle Body Work – Quarter Panel

There was quite a bit of rusted metal especially around the wheel wells. The driver’s side front quarter panel looks like it was once hit and then horribly repaired. It took a while to find a good replacement and then it had to be shipped via Greyhound Bus from California. Sometimes, I wish I lived out West. Greyhound takes forever to have things delivered. The panel is finally installed and more pictures coming soon.

Welding Wheel Well Patch

66 Bug Heater Channel Replacement

Heater channel replacement poses challenges and required complete replacement. Actually, the entire foundation, what bolts the body to the frame, needed replacing. The northeast, and abuse, took it’s toll on this bug. I needed entire heater channels components, front firewall and rear components. Make sure to brace the doors before cutting out the old channels. More pictures coming soon.

Replacing the 1966 Beetle Floor Pans

The floor pans were completely rusted out, so new ones were installed. The previous owner thought he could repair the shifter by cutting a huge hole in the center frame, but it’s been welded now. Preparing the pans took a lot of work by drilling out the existing spot welds, using up many bits. This was my first welding experience and I got better by the time I was done. One day, I’ll be able to afford a better welder with gas!